Alaska Airlines - Baggage Application

KEEPING PASSENGERS AND THEIR BAGS TOGETHER

Have you ever looked out your window seat and wondered how your baggage travels from the ticket counter and or connecting flight... to somehow successfully end up with you at your destination? It is not a simple process, which is why, until recently, approximately 6,000 bags per year are loaded onto the wrong planes and 16,500 bags miss thier connections - each costing roughly $85.00 per incident. In addition, 26,000 bags fail to be loaded on aircraft at a cost $1,100,00.00. This all totals up to huge potential savings, and an immeasurable opportunity to increase customer satisfaction.

RAMP AGENTS SCANNING BAGS ONTO A PLANE

KNOWING WHEN AND WHERE A BAG WAS LAST SCANNED

The key to keeping baggage and passengers together is always knowing the last known location of each bag and passing on this information to the appropriate parties at the right time. Replacing a paper-based system with live digital updates not only would allow for constant tracking of baggage but would also provide clean data in and out. This new workflow not only would save miss-loads and scans, but reduce the headcount required on the tarmac resulting in additional savings.

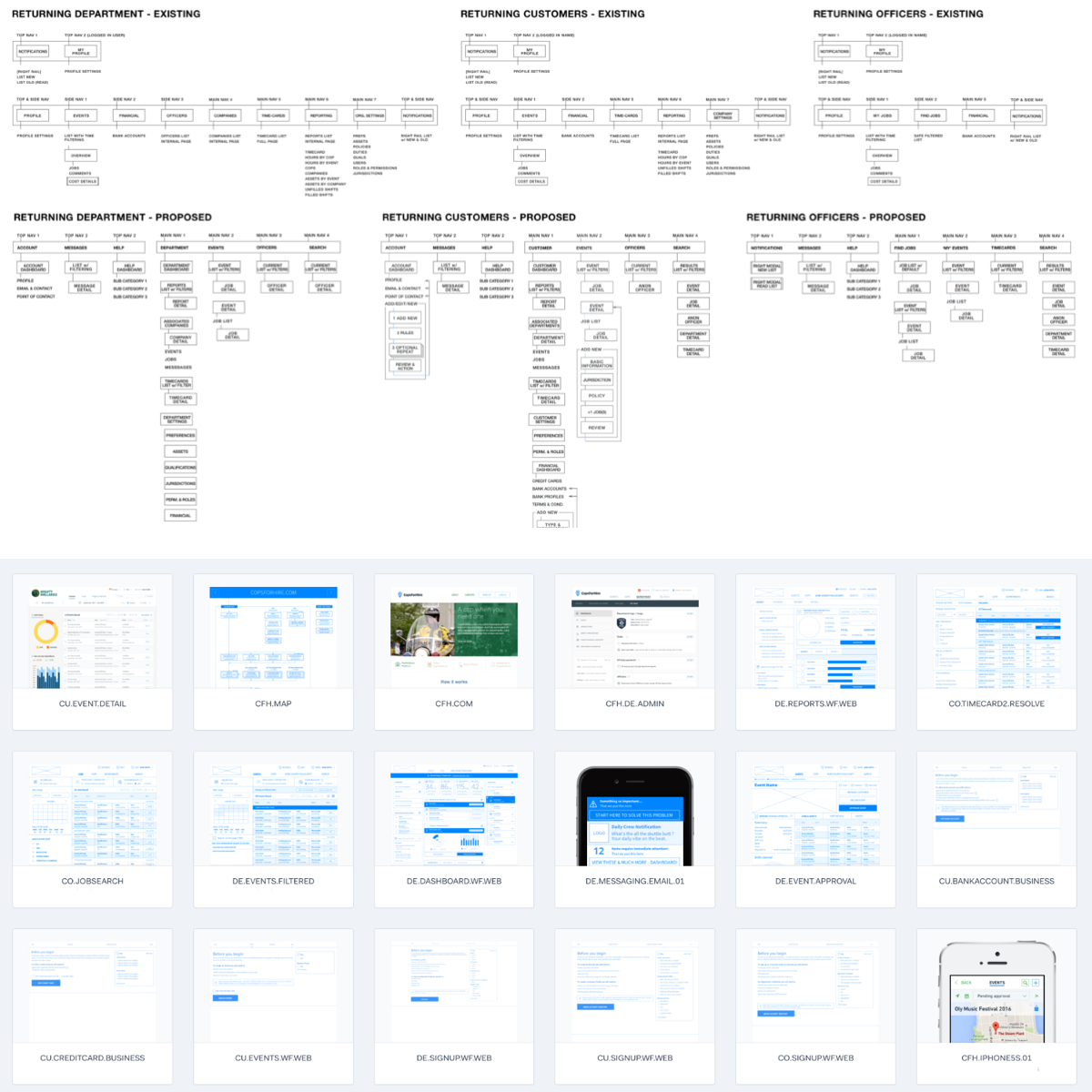

UNDERSTANDING THE INFORMATIONAL FLOW OF BAGGAGE

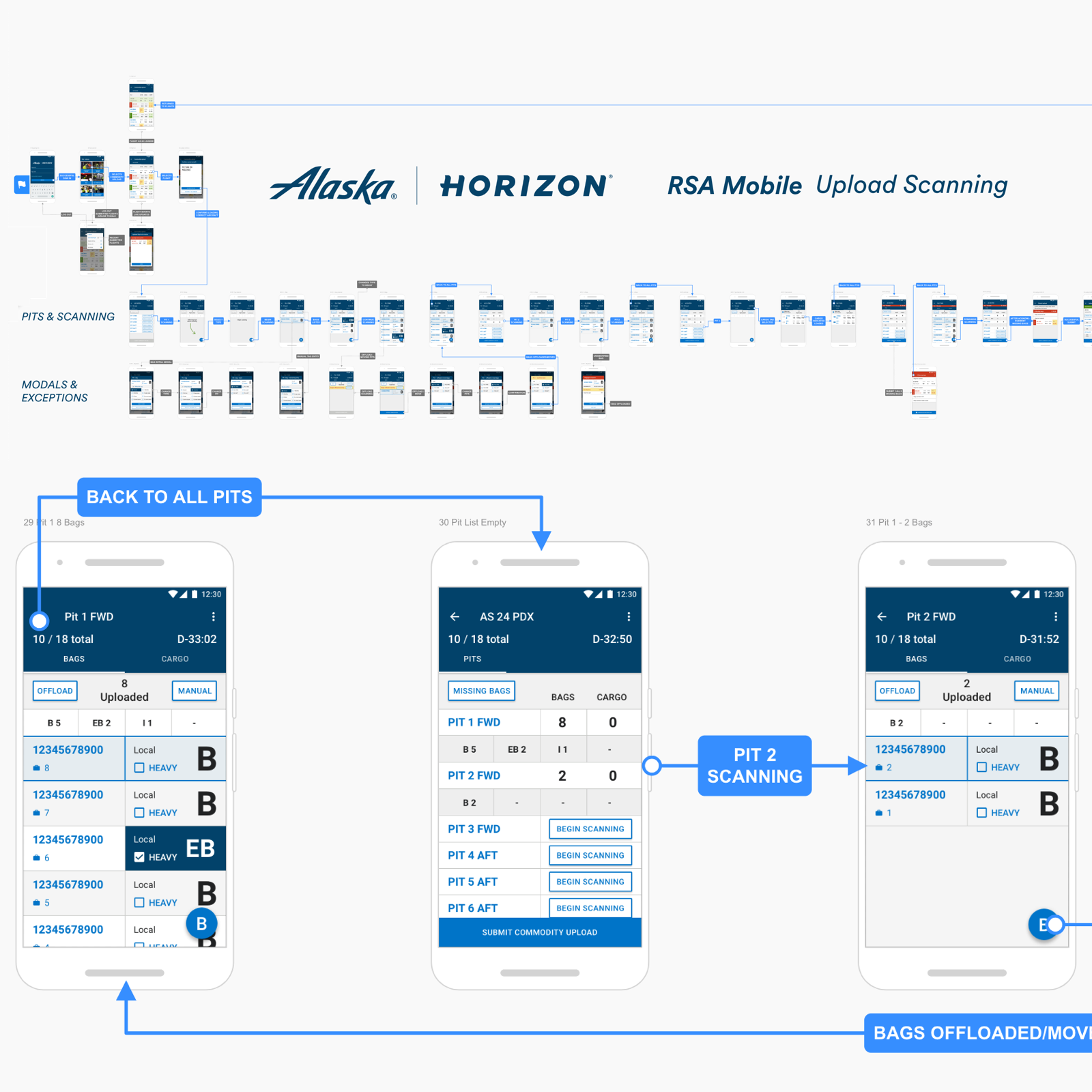

A UI DESIGNED WITH A MINIMUM AMOUNT OF INTERACTION

The challenges on the ground at the airport are many. Including cold weather, the agents wearing gloves, and an extremely noisy environment. In order to maintain the speed at which bags are loaded, it was clear that I had to keep the interaction with the application to a minimum. The entire application consists of 6 page types and three informational modals. Hardware buttons and haptics are used when at all possible, reducing the need to touch the screen.

RAMP AGENT NEW SCANNING WORKFLOW

WHEN EXCEPTIONS ARE THE RULE - OF SUCCESS!

The 'Happy path' of our user flow includes error screens - intending to alert the ground crew of incorrect bags. Currently testing BETAs in the field, we are already detecting incorrect bags and notifying the crew of missing bags. The end result of this projected is projected annual savings $5.4 million dollars - and an already measurable increase in satisfaction amongst the ground crew.

Prototype:

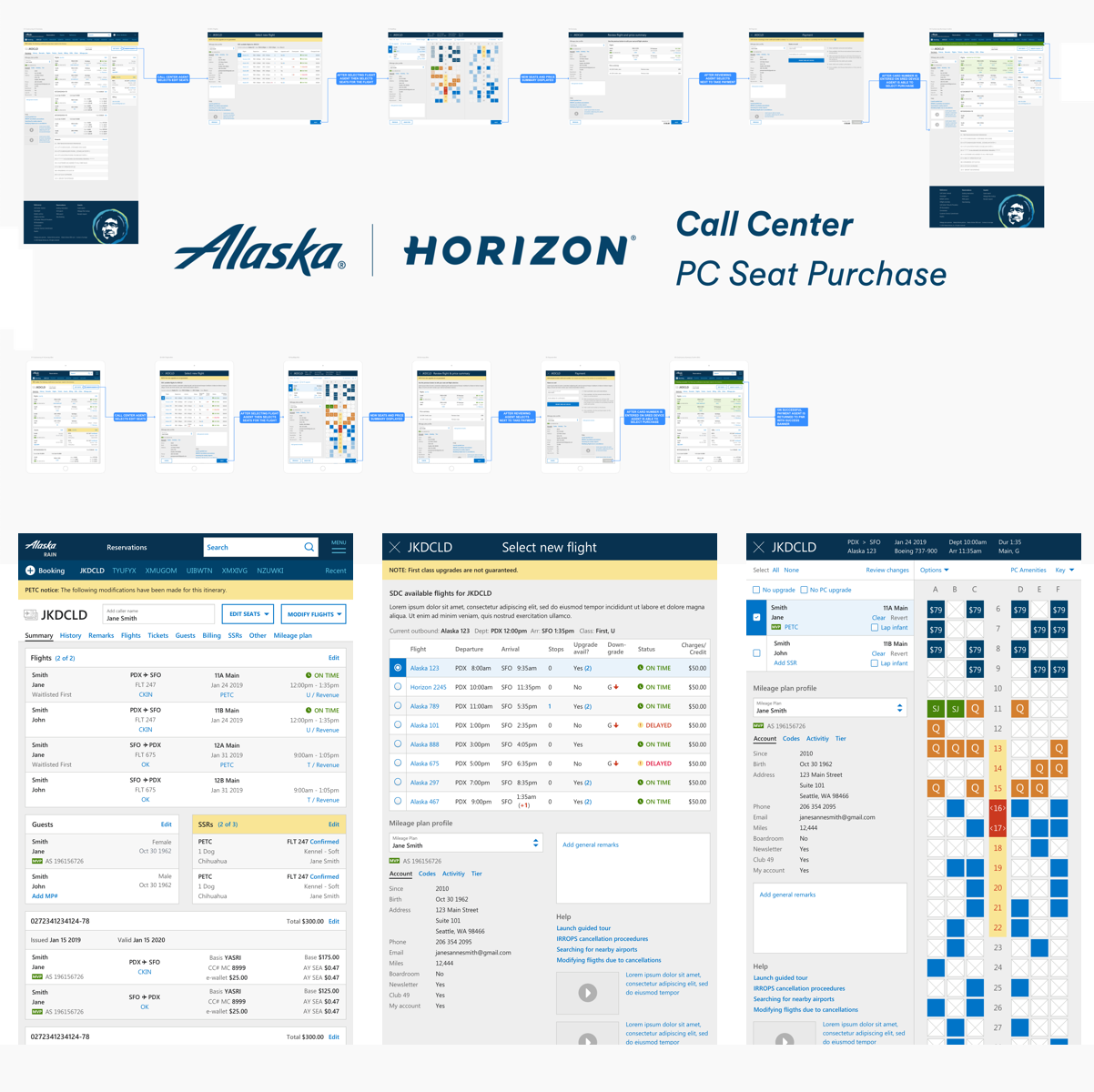

SHIPPING PRODUCT AND DETAIL OF VARIOUS SCREENS